Online Pharmaceuticals Machinery >>

Online FBD And RMG Inline

The Vacuum transfer systemis unique dry material transfer system for dust free and avoid to human touch. The vacuum transfer system is used in Pharmaceutical, Food, Agro Chemical, Sugar Industries and chemical. The system is use full for inline milling, sifting, blending, loading and unloading.

The principle of vacuum transfer has been proven to be a better way to move many types of material and a giant step over manual handling. The technology exists for moving virtually any material that can be pulled through a hose or tube. The system is consisting of Blower, Vacuum receiver system with filter, cyclone filter and Pipe.

The vacuum conveying systems designed specifically for the direct charge loading of blenders, mixers, sifter, milling, reactors or any vessel capable of withstanding a vacuum. The vacuum system can be provided mobile type with lifting provision to move one room to another room for loading and loading any machine.

Design is cGMP - Current Good Manufacturing Practices compliance.

Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304.

All contact parts AISI 316 & non contact parts AISI 304. Capacity available 100 Kg to 5000 Kg/hr.

Capacity available 100 Kg to 5000 Kg/hr. Can be used for transfer of products having bulk densities up to 1.0gm/cc.

Can be used for transfer of products having bulk densities up to 1.0gm/cc. Total Discharge no Retention.

Total Discharge no Retention. No segregation or degradation of Product.

No segregation or degradation of Product. No tool required for opening & cleaning.

No tool required for opening & cleaning.  Transfer can be completely automatic to avoid the manual handling of the material

Transfer can be completely automatic to avoid the manual handling of the material Fully automatic system, with timing controls and automatic air blow back system for filter cleaning.

Fully automatic system, with timing controls and automatic air blow back system for filter cleaning. Vacuum Blower and cyclone filter can be installed in out side production area.

Vacuum Blower and cyclone filter can be installed in out side production area. Avoids product waste, loss and contamination.

Avoids product waste, loss and contamination. Easy to clean and wash of contact parts.

Easy to clean and wash of contact parts. Option for Inline Milling, Sifting with Blender and Loading material to RMG, Tablet press& Vessel.

Option for Inline Milling, Sifting with Blender and Loading material to RMG, Tablet press& Vessel.

Simplified construction, uniform Human Machine Interface

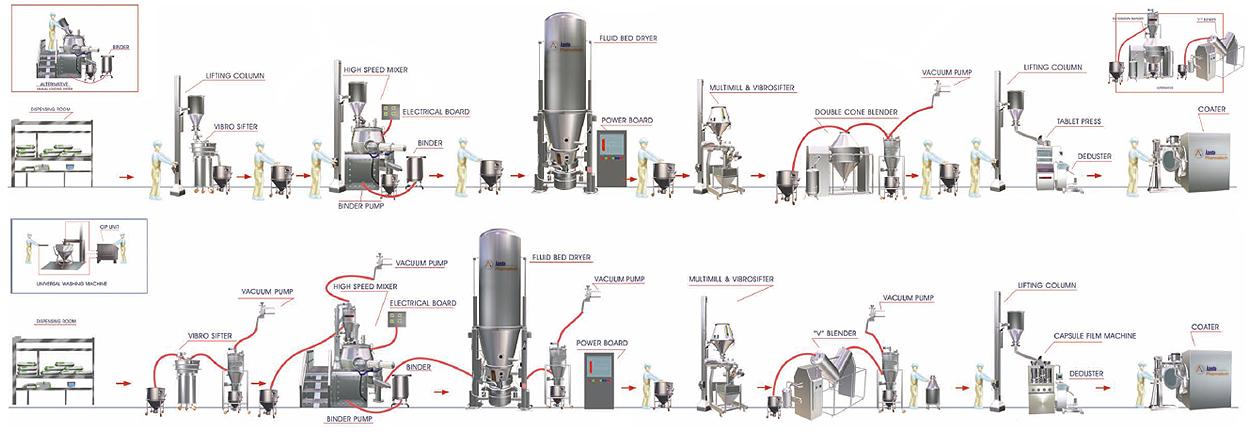

As opposed to tailor-made granulation lines, the most important functions of online Granulation are installed by default. “The high level of standardization now enables us to fulfill customer demands for a complete and quickly available system at the accustomed high quality,” says Scholz. Thanks to the easy alignment of machine components on site, the granulation unit can be installed quickly and easily. All process and cleaning steps can be controlled via recipes. The operator interface is a 21-inch touch screen with user-friendly navigation.

Smooth product flow through integrated wet mill

The process for manufacturing pharmaceutical granules begins by pneumatically filling the high-shear mixer. The mixing device azestomix, which is driven from below, mixes and granulates the active ingredients and excipients. The highshear mixer is emptied via the equally newly developed, integrated wet mill.

Communication between mill and azestoline granualtion ensures that only as much product is emptied as the mill is able to process, which prevents the mill from clogging. A pneumatic transfer pipe subsequently transfers the wet product to the Granulation fluid bed module, where it is dried through the inflow of the proven Disk jet distribution plate. The function of process filters is crucial to obtain high yields: for this reason, Bosch has developed a new process filter, where the elements are serially cleaned with compressed air pulses. At the end of the drying process, the product is emptied by a dry mill.

Apart from the high-shear mixer, granulation can also take place in the fluid bed by using a tangential or top spray process. GranuLean is available for a containment level of up to OEB3 (Operational Exposure Band). The machine remains closed during operation, while inflatable seals on the product containers provide for an optimum draught proofing. Moreover, the integrated cleaning system ensures an even easier handling.

Tablets and capsules in line

Suitable handling equipment makes it possible to combine the new granulation unit to a compact line, for instance with the new tablet presses of the Manesty TPR range. Alternatively, the granule can be filled into stick packs or capsules, for example with the new GKF 2600 capsule filling machine from Bosch.

Our Products Range...

Tablet Compression Machines

Tablet Press – High Speed

Single Sided Tableting Machine

Double Sided Rotary Tableting Machine

Bolus / Slugging Tablet Press – Heavy Duty

Granulation Equipments

Drying Machines

Particle Size Reduction Machines

Milling & Sifting Equipments

Blending & Mixing Equipments

Encapsulation Machine

Coating Equipments

Liquid Syrup Manufacturing Plant

Bottle Washing Machine

Automatic Linear Bottle Rinsing Machine

Liquid Filling Machine

Semi-Automatic Volumetric Liquid Filling Machine

Automatic Volumetric Liquid Filling Machine

Semi-automatic overflow liquid filling machine

Automatic overflow liquid filling machine

Cap Sealing Machine

Automatic Single Head Capping Machine

Automatic Multi Head ROPP Cap Sealing Machine

Automatic Multi Head Screw Capping Machine

Automatic Dosing Cup Placing Machine

Labeling Machine

Automatic High-Speed Sticker Labelling Machine

Automatic Self Adhesive Vertical Labeling Machine

Accessories